Suitable for low room heights, even with large systems

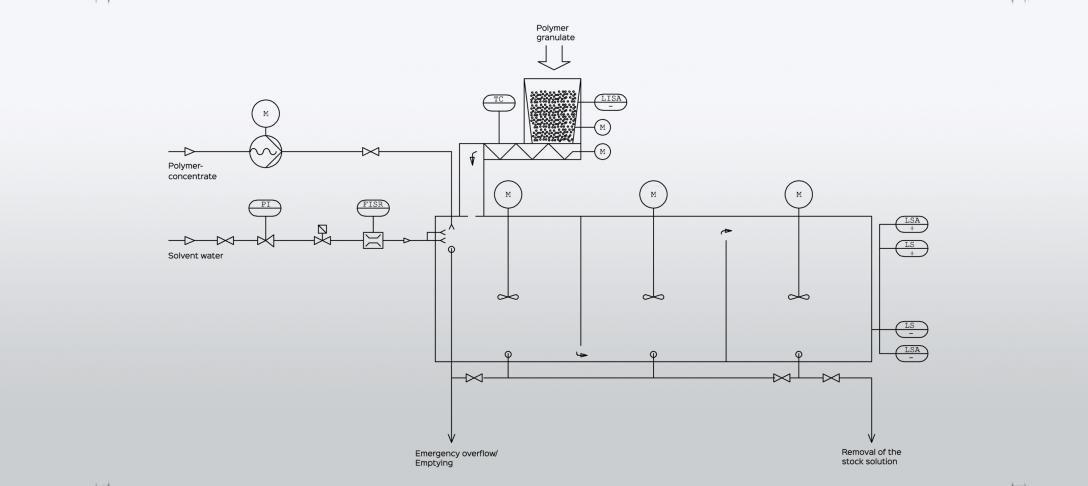

Fully automatic three-chamber system for powdered and/or liquid polyelectrolyte.

The 3K systems consist of three interconnected chambers. The polymer solution is prepared in the first chamber and reaches the second chamber using the displacement principle. During this time, the solution matures. The finished working solution is finally displaced into the third chamber, the so-called dosing chamber, from where it can be continuously dosed.

Suitable for low room heights, even with large systems

User-friendly due to low height

Proven concept

For enquiries about our products, please contact us at: office@eurodos.at

Eurodos Dosiertechnik GmbH - a VTA Group company - successfully completed the project with its partner Krevox.

Magyar Suzuki also relies on expertise from VTA and Eurodos.

What does VTA have to do with the economical and environmentally friendly extraction of quartz sand? Quite a lot, as an example from Slovakia proves.

Fully automatic two-chamber tower system in round container form for powdered and/or liquid polyelectrolyte.

Fully automatic two-chamber pendulum system for powdered and/or liquid polyelectrolyte.

Each dosing station is manufactured precisely to your specifications.