Thanks to our many years of experience in wastewater treatment, we carry out well-founded wastewater analyses

Discover a completely new dimension in water technology and plant engineering.

Your partner for complete solutions in the field of wastewater treatment

As a manufacturer in plant engineering, we offer our customers a comprehensive solution from a single source

Our high proportion of in-house production enables flexible solutions of the highest quality

Our specialist staff have the necessary expertise to handle tasks professionally

We realise projects precisely with our modern machinery

Our 24/7 service guarantees fast responses and continuous support

From analysing the raw wastewater to commissioning and training by experienced process engineers - we support the entire process. Our expertise lies in the production of components for dosing technology solutions, plastic tanks, plastic pipework and more.

With 3D visualisations and detailed planning, we ensure that wastewater processes run efficiently and reliably. Our spacious production buildings enable us to manufacture high-quality components, which are installed on site by our experienced assembly team.

After successful commissioning, we hand over the system to the customer and offer a comprehensive after-sales service for long-term support.

Embracing the Circle of Sustainability!

We develop a solution concept for each customer that is customised precisely to the respective requirements.

- PLANT PLANNING

- PRODUCTION OF COMPONENTS

- PLANT ASSEMBLY & IBN

- PLANT ENGINEERING SERVICE

- PROCEDURAL ANALYSIS

- PROCEDURAL ANALYSIS

- OPTIMIZATION INVENTORY

Customized solutions

Almost every production plant produces wastewater with different compositions. This means that the requirements for a wastewater treatment plant are always different and require different treatment methods.

VTA uses its in-depth expertise to plan and realise your wastewater treatment plant.

Our range of services includes pipeline construction, the construction of pumping stations, the manufacture of tanks, screening and flotation systems, dosing stations, pipe reactors/flocculators, sludge dewatering units, blower and aeration installations, exhaust air treatment (scrubbers, biofilters, activated carbon, etc.), switch cabinet construction and PLC programming.

State-of-the-art system technology

We engineer and produce high-performance water treatment systems, incorporating the most up-to-date technologies, customizable to any size needed, and crafted to the most rigorous quality benchmarks.

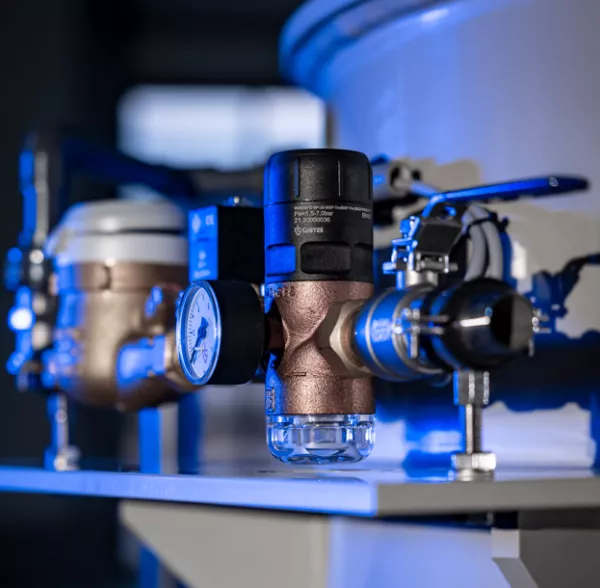

VTA dosing technology

Durable and efficient dosing solutions.

VTA storage tank

The storage tank makes handling precipitants and other chemicals safer, more precise and more convenient.

VTA underground tank

Our VTA underground tank offers the option of safely storing and dosing liquid products underground.

VTA polymer solution station

VTA polymer dissolving stations guarantee excellent system efficiency and highly economical consumption.

VTA dosing station

Eurodos precipitant stations as an economical complete solution.

VTA MicroTurbine

With the MicroTurbine, VTA is revolutionising the generation of electricity and heat in sewage treatment plants.

VTA mudinator®

Cost reduction with VTA mudinator® by significantly reducing the amount of sludge to be disposed of.

VTA Service & Plant Optimisation

Our VTA energy & plant check helps you to cut costs by reducing your energy requirements.

Plant dimensioning

Would you like to know which size of dissolving system and dosing station is best suited to your requirements? Simply calculate it yourself with our practical online service tool for plant dimensioning!

Plastics plant engineering

In this area, our continuously trained specialists mainly process PP, PE and PVC into pipelines and containers and assemble them at the customer's premises. From waste water containing highly aggressive media such as acids and alkalis to ultra-pure water applications, we can plan, manufacture and install any solution on site.

Double-walled storage tanks, round or square, are either supplied ready-made or welded on site at the customer's premises. Everything is possible with VTA.

VTA Flotation Facilities

Diverse process technologies, whether physical, chemical, or hybrids, necessitate tailored solutions.

Leveraging our profound expertise and dedicated laboratory team, we discern the optimal process, devise comprehensive system blueprints, and execute them seamlessly.

Liner Solution

Tailored plastic linings crafted from PE or PP present VTA’s economical answer for constructing and refurbishing concrete tanks and various containers.

Skilled and certified VTA personnel execute the construction and installation. Precision cutting of premium PE sheets on-site, secured firmly with screws, and expertly welded ensure top-notch results.

VTA’s plastic liners elevate containers of diverse types to meet stringent standards.

VTA Mobidos

Our plug & play dosing unit including storage tank with a capacity of up to 25 m³ offers you an uncomplicated solution without any structural measures. Thanks to frost protection, the system can be used all year round. The commissioning time at the customer's premises is extremely short. An electrical interface for remote data transmission is integrated. We offer customer-orientated financing options such as purchase, hire and hire purchase.

- Plug & Play

- Dosing unit including storage tank with a capacity of up to 25 m³

- No structural measures required

- Frost-proof and can be used all year round

- Extremely short commissioning time at the customer's premises

- Including electrical interface for remote data transmission

- Customer-orientated financing options (purchase, rent, hire purchase, etc.)

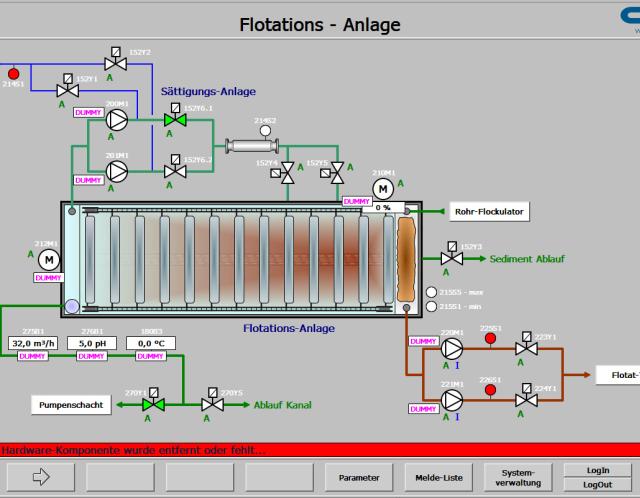

VTA Switch Cabinet Construction and PLC Programming

Switchgear is the centrepiece of any production or industrial plant. As every wastewater and the cleaning processes are always slightly different, the control system is particularly challenging. To meet these challenges, we plan and produce our control cabinets and control systems ourselves.

OUR SERVICES:

- Enclosure planning in EPLAN P8

- Switch cabinet production

- PLC programming in the Siemens TIA Portal

- Visualisation and data transmission

Your customised solution awaits you!

From analysing the raw wastewater to commissioning and training by experienced process engineers - we support you throughout the entire process.

Contact us now:

VTA Plant engineering Folder

Discover all the details of VTA Plant engineering in our digital e-paper, which you can read conveniently and is also available for download.