Small space requirement due to compact shape (two chambers on top of each other)

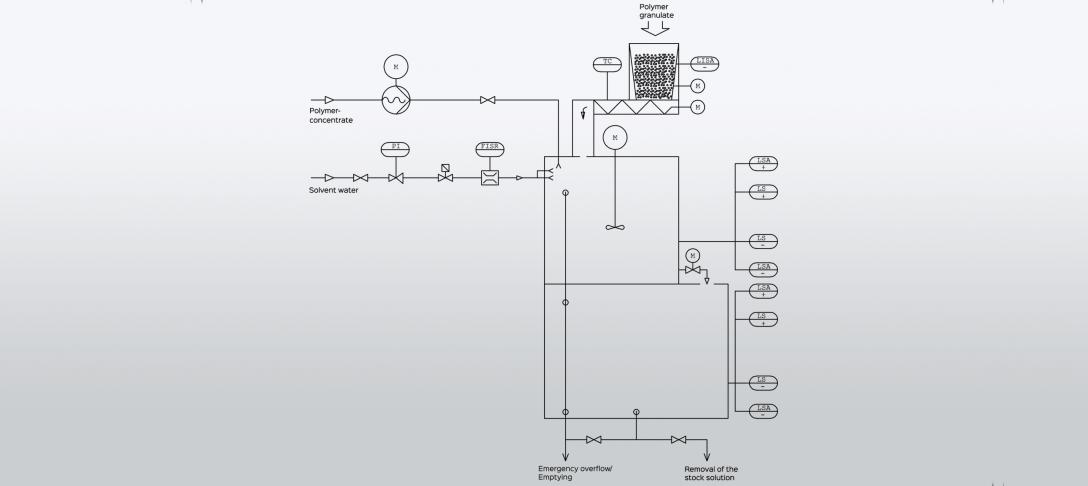

Fully automatic two-chamber tower system for powdered and/or liquid polyelectrolyte.

The 2KT systems consist of two chambers located one above the other. The polymer solution is prepared and matured in the upper chamber. If required, the motorised flap opens and discharges the matured solution into the dosing container below, from which it can be continuously dosed.

Small space requirement due to compact shape (two chambers on top of each other)

Two separate containers prevent short-circuit currents

Energy-saving, as only one agitator is required

For enquiries about our products, please contact us at: office@eurodos.at

Eurodos and VTA system products in use. A new dosing system for optimum results.

The fully automatic polymer dissolving station helps to save costs.

Fully automatic two-chamber tower system in round container form for powdered and/or liquid polyelectrolyte.

Fully automatic two-chamber pendulum system for powdered and/or liquid polyelectrolyte.

The Eurodos storage tank makes handling precipitants safe, precise and convenient.