Every wastewater treatment plant has its own special challenges. VTA not only sells products, but also develops solutions - even for very special conditions.

Estavayer-le-Lac is a medieval town on Lake Neuchâtel in the canton of Fribourg that is well worth a visit. The largely preserved historic old town with its narrow streets and Chenaux Castle on a steep slope above are popular with tourists. Estavayer-le-Lac is home to the ERES wastewater treatment plant, which has a special feature: In addition to around 5000 m3 of municipal wastewater, around 4500 m3 of wastewater from a food industry company also ends up here every day. This industrial wastewater is pre-treated separately in its own high-load biology before it reaches the second biological stage, where it is mixed with the municipal wastewater. In total, the plant has a capacity of 120,000 PE.

However, high-load pre-treatment in particular has repeatedly caused problems for those responsible. This was due to shock loads, higher temperatures, abrupt fluctuations in the pH value and other properties that are characteristic of industrial wastewater. In addition, there were certain filamentous bacteria, such as Nostocoida limicola and type 1701, which feel particularly at home in industrial wastewater and under high-load conditions.

Suspended solids caused problems

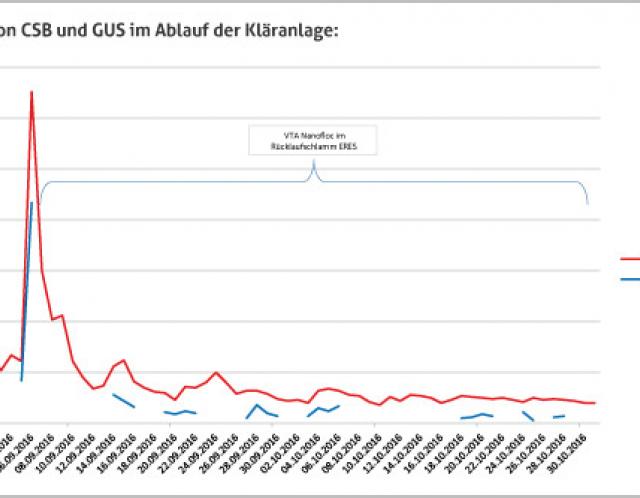

This led to high sludge indices and ultimately to sludge discharge in the secondary clarification of the pre-treatment. From there, the sludge reached the second biology. Here, too, filamentous bacteria (Nocardia) increased, floating sludge appeared in the aeration tanks, the secondary clarifiers were cloudy and the COD in the effluent was very high (sometimes > 100 mg/l).

"For a long time, I was reluctant to tackle our problem with chemicals. But after talking to David Rietsch and a successful test on site, our continuous dosing system has now been ensuring good water quality in the wastewater treatment plant's outlet for more than six months. Thank you VTA!"

Yves Bourdillord, Operations Manager

After detailed microscopic analyses by VTA biology experts, VTA employee David Rietsch recommended the use of VTA Nanofloc®. The

The optimum dosing point was finally determined to be the return flow of the second biology, which is not only directly influenced by this power product from VTA in this way. Part of the activated sludge from the second biology is also transported to the high load. As a result, VTA Nanofloc® also reaches the high load, where it greatly improves floc formation and floc structure, increases settling behavior and combats filamentous bacteria.

Clearly positive results

The results are clear: even in the aeration tanks of the low-load biology, there is now no more floating sludge, the turbidity has largely disappeared, the depth of visibility has increased significantly and the COD has fallen from peak values of over 100 to less than 30 mg/l. It is therefore possible to fundamentally optimize both the high-load and low-load biology with just one dosing point.

The conclusion of those responsible in Estavayer-le-Lac: “The continuous use of VTA Nanofloc® ensures stable and absolutely reliable, trouble-free plant operation. The high level of efficiency and effectiveness allows a low dosage and is therefore also convincing in economic terms.

Practical report from the VTA Group's knowledge magazine “Der Laubfrosch”, issue 76