VTA Nanofloc®: Impressive long-term results at the ADO Goldkante treatment plant

Energy consumption reduced

VTA Nanofloc® is not only unrivalled as a ‘fire brigade’ in times of crisis or emergency at treatment plants. Used over the long term, the high-tech product from VTA ensures stable plant operation that is at the same time particularly cost-effective. An example from Lower Saxony in Germany shows that VTA Nanofloc® can massively reduce energy consumption and therefore also operating costs. At the ASD ADO treatment plant in Papenburg, VTA Nanofloc® has now been in use for almost four years. This is a municipal 8,000-PE plant dedicated exclusively to the treatment of wastewater from ADO Goldkante, the world’s leading manufacturer of curtains and decorative fabrics based in the Aschendorf district. The ‘Goldkante’ (golden edge) is in fact a gold-coloured lurex thread, which together with a weighted ribbon forms a border close to the floor, and has been a hallmark of the quality of the curtains produced in the Emsland region for more than 40 years. Working with another company, DTF, ADO is looking to increase its production of textiles for the automotive industry in the future.

High operating costs in the past

One of ADO’s specialities is the manufacture of flame-retardant and antibacterial curtains; the special treatment these materials require has an impact on the wastewater from production. Poor flocculation and high operating costs prompted the treatment plant’s manager, Rolf Wessels, to use VTA Nanofloc® for the first time in May 2008 – with the usual rapid success: visibility depth and other parameters such as COD in the discharge improved quickly and sustainably. And not only that: the use of VTA Nanofloc® has resulted in annual “savings in the five-figure range”, as confirmed by Wessels (see interview above).

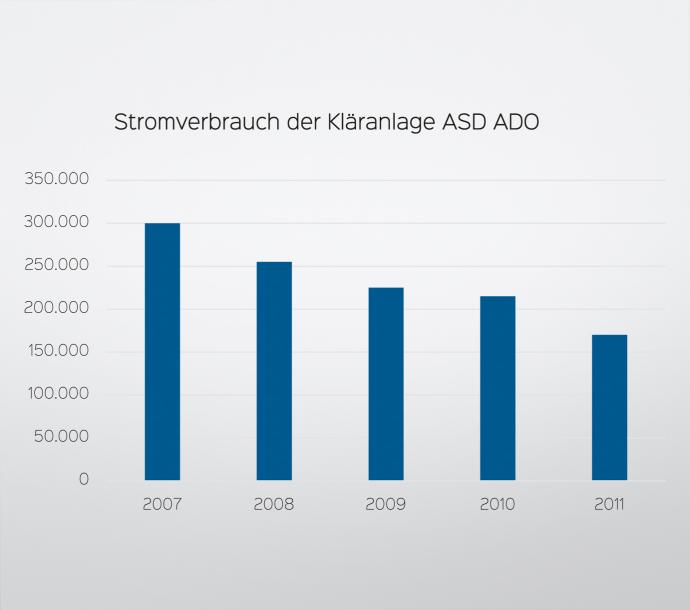

The plant’s total energy consumption fell from 297,000 kWh in 2007 to 169,000 kWh in 2011 – despite the fact that inflow loads remained unchanged during this period in terms of both quality and quantity.

As an experienced plant manager who never loses sight of costs, Rolf Wessels had long recognised the potential for optimising the treatment plant. But the sludge properties at the time did not allow implementation of the necessary measures – the plant was often running at its limits, so ensuring reliable operation was of course the top priority.

Exploiting optimisation potential

Thanks to VTA Nanofloc®, the sludge properties have improved to the extent that Wessels can now fully indulge in one of his hobbyhorses: optimising the plant using innovative methods. As a chamber of commerce-certified energy manager, he has already implemented forward-looking energy saving and optimisation measures at the municipal treatment plant in Papenburg (48,000 PE).

Savings in the five-figure range

Mr Wessels, you have been using VTA Nanofloc® in practice in day-to-day plant operations for almost four years now. What has been your experience?

The treatment plant now has a better treatment capacity, it is easier to control and we achieved five-figure savings in 2011.

So optimisation measures involving excellent plant management and an intelligent product save a lot of money. How do these savings come about in detail?

On the one hand, as a result of lower energy costs and, on the other, because we were able put optimisation measures in place that would not have been possible without VTA Nanofloc®. Because the plant is now stable, we can use personnel resources for other important jobs. Thanks to VTA Nanofloc®, we have also been able to declare lower discharge values to NLWKN, the Lower Saxony Water Management, Coastal Defence and Nature Conservation Agency, and to adhere to them reliably. This means that we now pay lower wastewater charges.

How satisfied are you with VTA in general?

VTA products, service and consulting are very good. I also appreciate their magazine, ‘Der Laubfrosch’, which takes a detailed look at many issues relating to wastewater.

Electricity consumption at the ASD ADO treatment plant (see upper graphic)

Real savings through long-term use of VTA Nanofloc®: energy consumption at the ASD ADO treatment plant fell by an impressive 43% – from 297,000 kWh in 2007 to 169,000 kWh in 2011.

Field report from the VTA Group’s scientific journal “Laubfrosch”, issue 56

The treatment plant now has a better treatment capacity, it is easier to control and we achieved five-figure savings in 2011.

Richiesta

Volete ricevere ulteriori informazioni sui nostri prodotti?

Contattate i nostri esperti e insieme troveremo la soluzione giusta.