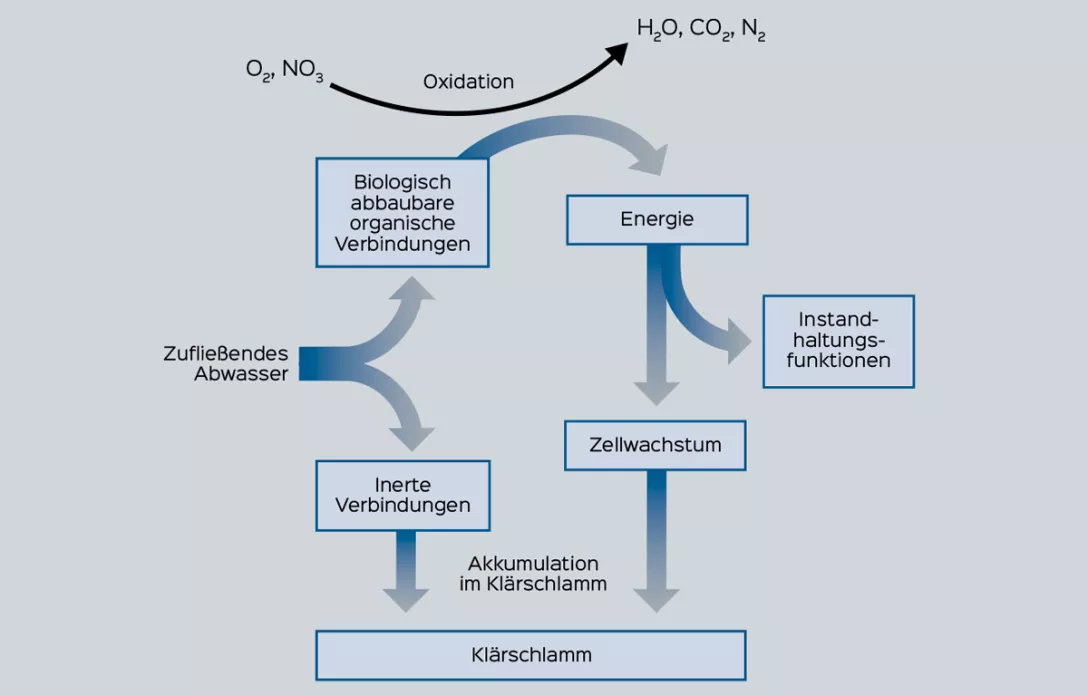

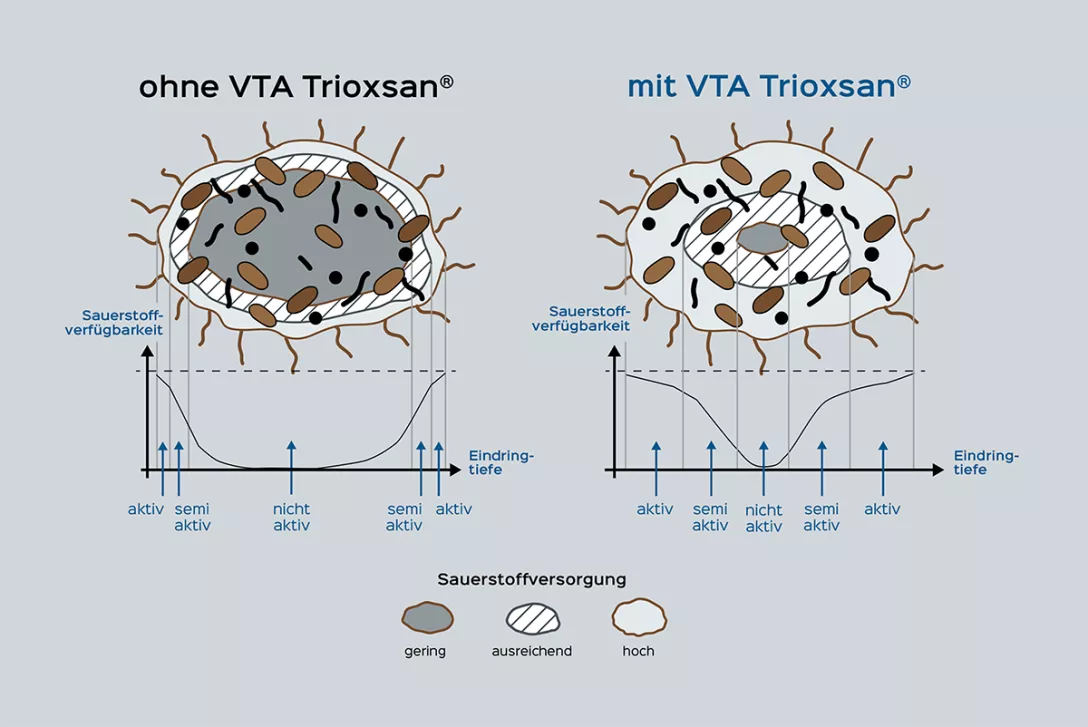

Oxygen-assisted phosphorus elimination:

Supports phosphate precipitation efficiently and sustainably. Your wastewater treatment plant is not only freed from pollutants, but also receives additional bound oxygen, which promotes biodegradation and reduces energy costs.